5.1.6. Performance of a screw

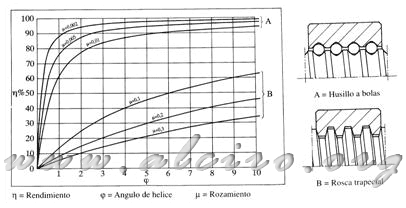

The analysis conducted so far do not take into account the losses caused by friction in these systems have been considered ideal without losses. When one takes into account the friction, the above equations must be multiplied by a coefficient of performance. In the case of the spindle (screw) this ratio depends on the slip system that is used as shown in Figure 5.14.

Figure 5.14. Performance and coefficient of friction of two types of spindles.

The screws are divided into two specific groups, derivatives of ball bearing and friction nut / screw. Ball screws in the coefficient of friction is very low due to rolling between the elements and the small contact area, resulting in high mechanical performance, between 90 and 95%. In Figure 5.14 illustrates the difference between the ball screws and traditional trapezoidal thread. When one considers the performance of the spindle, the equation 5.33 is:

(5.34)

(5.34)

where

η 1 = screw efficiency (beads from 0.9 to 0.95)

Figure 5.14. Performance ball screws in normal and reverse operation.

In reverse operation, if it transforms linear motion into rotary motion the torque is calculated by the equation:

(5.35)

(5.35)

where

efficiency η 2 = reverse (beads from 0.9 to 0.95)