1.3.2. Hybrids of three and five stages

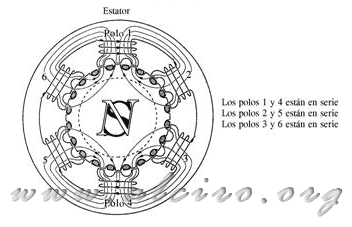

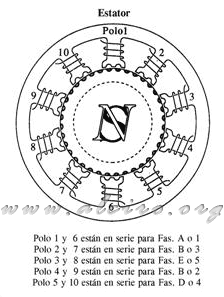

This type of engines are unpopular. At this number of stages, the designer opts for brushless AC motors. A typical structure of three phase motor sectioned and showing the magnetic flux lines can be seen in Figure 2.19. Figure 2.20 shows a similar illustration of a five-phase hybrid motor with 36 teeth on the rotor.

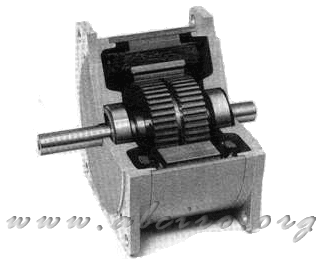

Figure 2.18. Cutting a hybrid stepper motor.

Figure 2.19. Cross section of a hybrid three-phase motor and 20 teeth on the rotor.

With the increasing number of phases, apart from increasing and greatly complicate the control circuit, provides such other better dynamics and a considerable increase in the number of steps.

A number of 200 steps per revolution is possible to obtain a 2-phase motor. 500 to 1000 steps per revolution is possible with a 5-phase motor, and 300 steps are available with 2 engines and 3 phases.

The use of five-phase motors in a closed loop control is anti economic, but this engine has an excellent dynamic response in a normal open-loop system.

Figure 2.20. Cross section of a five-phase hybrid motor and 36 teeth on the rotor.