5.1.4.2. Example of calculating the velocity profile

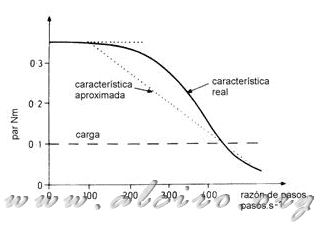

Example: stepper motor has a length of 15 degree steps and a characteristic torque / speed pull-out as shown in Figure 5.8, it is moved to accelerate a load inertia of 2 * 10-4 Kg * m 2 and a pair of 0.1 N * m. Obtain the velocity profile curve to accelerate the system optimal.

The pull-out reason for this system is 435 steps * s-1, so at this rate the pull-out torque of the motors is equal to load torque.

The variation of pull-out torque with speed can be approximated to a straight line, as shown by the dotted line in Figure 5.8. T (f) is approximate to the function:

Figure 5.8. Characteristics of two pull-out showing the linear approximation.

\ =\ 0.35\ N*m\ \ \ 0<f<100\ pasos*s^{-1}\\ y\ =\ 0.426-0.00075*f\ N*m\ \ 100<f<435\ pasos*s^{-1}\\ T_L(f)=0.1\ N*m) (5.20)

(5.20)

For reasons of steps up to 100 steps * s -1:

-T_L(f)}\ =\ \ \int_{0}^{t}\frac{\partial f}{0.25}\ =\ 4*f\ (N*m*s)^{-1}) (5.21)

(5.21)

The step length is 15 degrees = 0.262 radians = 2 * π / n * p. From Equation 5.21, the time taken to reach the ratio of step f is:

(5.22)

(5.22)

Thus the velocity increases linearly with time until reaching the 100 steps * s -1, reached after 21 ms.

For reasons of way between 100 and 435 steps * s -1:

-T_L(f)}\ =\ \ \int_{0}^{100}\frac{\partial f}{0.25}+\int_{100}^{f}\frac{\partial f}{0.426-0.00075*f}\\ =\ 9630-1333*log(1305-3*f)\ (N*m*s)^{-1}) (5.23)

(5.23)

From Equation 5.19, the time needed to reach the ratio of steps in the range of 100-435 steps * s -1 is therefore:

![Time needed to reach the ratio of 100 to 435 steps t\ =\ \frac{2*\pi *J*A}{n*p}\ =\ 0.0262*2*10^{-4}*[9630-1333*log(1305-3*f)]\\ =\ 0.503-0.0679*log(1305-3*f)\ s](http://www.alciro.org/cgi/tex.cgi?t\ =\ \frac{2*\pi *J*A}{n*p}\ =\ 0.0262*2*10^{-4}*[9630-1333*log(1305-3*f)]\\ =\ 0.503-0.0679*log(1305-3*f)\ s) (5.24)

(5.24)