2.2.5.2. Calculation of dynamic torque (pull out)

Now we need to establish the relationship between the fundamental component of voltage and current in phase with the pair. The mechanical power output of the phase is simply the product of current through the phase and induced voltage.

*I.cos(\omega *t-\sigma -a)\\ =\frac{\omega *\psi _M*I*cos(a)}{2}+\frac{\omega *\psi _M*I*cos(2*\omega *t-2*\sigma -a)}{2}) (3.25)

(3.25)

From Equation 3.25 The components that vary over time have no interest and is only necessary to evaluate the first term. For a hybrid of two phases, the total mechanical power is:

) (3.26)

(3.26)

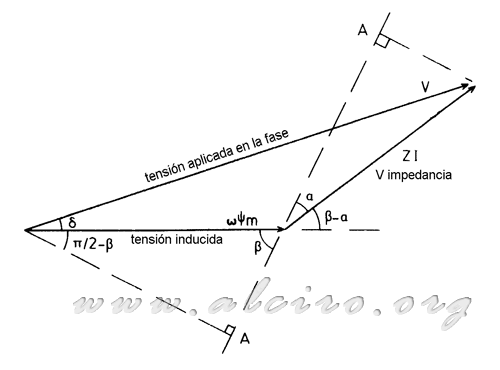

the term Icos (a) is eliminated from this equation with the construction of the line AA 'in the vector diagram (Figure 3.24) at an angle to the vector ZI.

Figure 3.23. Construction of the vector diagram for the expression I * cos (a).

The expression for the length of the line AA 'is projecting the vectors ωδ m, V and ZI on the line:

\ =\ \omega *\psi _M*cos(\beta )+Z*I*cos(\alpha ))

then.

\ =\ \frac{V*sin(\frac{\pi }{2}-\beta +\sigma)-\omega *\psi _M*cos(\beta ) }{Z}\\ =\ \frac{V*cos(\beta -\sigma)-\omega *\psi _M*cos(\beta ) }{Z}) (3.27)

(3.27)

Substituting I * cos (α) of equation 3.27 in equation 3.26.

-\omega ^2*{\psi _M}^2*cos(\beta ) }{Z}) (3.28)

(3.28)

But the mechanical power output is equivalent to the product pair for speed. From equation 3.18 the velocity is ω / d and thus:

![Torque equation of a hybrid stepper motor Par\ =\ \frac{Potencia}{Velocidad}\ =\ \frac{d*[\psi _M*V*cos(\beta -\sigma)-\omega *{\psi _M}^2*cos(\beta )] }{Z}](http://www.alciro.org/cgi/tex.cgi?Par\ =\ \frac{Potencia}{Velocidad}\ =\ \frac{d*[\psi _M*V*cos(\beta -\sigma)-\omega *{\psi _M}^2*cos(\beta )] }{Z}) (3.29)

(3.29)

to find the parameters fixed speed the only variable in the equation 3.29 is the load angle (σ). The variation of this is consistent with the load, the torque of the motor and load are equal. When applied load, the load angle is similar to the expression for the torque. Analyzing the equation 3.29 The maximum torque occurs when β = σ, then:

![Equation pull-out torque of a stepper motor Par_{(Pull\ out)}\ =\ \frac{d*[\psi _M*V-\omega *{\psi _M}^2*cos(\beta )] }{Z}\\ =\frac{d*\psi _M*V}{\left( R^2+\omega ^2*L^2 \right)^{1/2}}-\frac{d*\omega * {\psi _M}^2*R}{\left( R^2+\omega ^2*L^2 \right)}](http://www.alciro.org/cgi/tex.cgi?Par_{(Pull\ out)}\ =\ \frac{d*[\psi _M*V-\omega *{\psi _M}^2*cos(\beta )] }{Z}\\ =\frac{d*\psi _M*V}{\left( R^2+\omega ^2*L^2 \right)^{1/2}}-\frac{d*\omega * {\psi _M}^2*R}{\left( R^2+\omega ^2*L^2 \right)}) (3.30)

(3.30)

A low-speed torque curve is equivalent to pull out (δψ m V) / R. This pair can also be deduced by the static torque characteristics, using the method described in section 3.2.2, the magnetic flux (ψm) can be expressed based on the terms of the static torque peak.

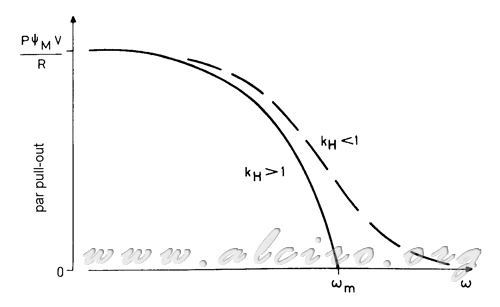

When the ratio of steps increases, the dynamic torque (pull out) is reduced gradually to zero level at a certain speed ω m (Figure 3.25).

Figure 3.25. Waveform torque / speed obtained in the calculation of pull-out torque for a hybrid stepper motor.

For another response, the property is asymptotic to the axis T = 0, the pair is tangent to zero at a ratio of infinite steps.

Equating equation 3.30 to zero a couple get the maximum speed ωm:

^{1/2}}-\frac{d*\omega * {\psi _M}^2*R}{\left( R^2+\omega ^2*L^2 \right)}\ =\ 0)

and therefore;

^{1/2}}) (3.31)

(3.31)

be KH = WMR / VL motor constant. For equation 3.31 The real value of the maximum frequency of operation can only be obtained if KH is greater than unity, in this case the square root in the denominator can be evaluated. The maximum rate of steps for the equation 3.31 is:

(3.32)

(3.32)

The maximum operating frequency is obtained from equation 3.31, is proportional to the total resistance of phase (R), so if the engine has to operate at high speed, the power circuit must include strong resistance.

For the selection of an engine has to work at high speed is desirable that the value of KH is as low as possible, so that the denominator of the expression to obtain the maximum frequency is minimized.