5.1.4. Optimal velocity profile

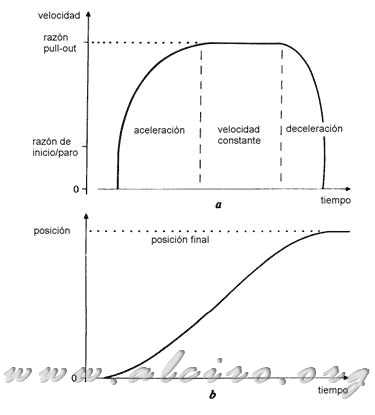

In general the reason for starting the stepper motor is much smaller than the ratio of pull-out steps, the positioning time can be reduced substantially if the engine is accelerated rigorously until it reaches the right pull-out . To reach the final position, the ratio of steps is gradually reduced from the rate of displacement until the motor stops. The graph of the ratio versus time steps in which the motor moves between the start position and end position is commonly referred to as (velocity profile), a typical example is shown in Figure 5.6.

Figure 5.6 Acceleration at a rate of pull-out and slow down to the final position.

a. - optimal speed profile.

b. - Response corresponding to the position / time.

In this we can see that the ratio of deceleration is much faster than the acceleration, because the load torque tends to slow the motor system and is able to develop more torque during deceleration than acceleration. In other words the burden of system helps to make the arrest.

There are several methods to generate the optimum speed profile, or approximations to it in the next section provides one of these, but the overriding reaction is that the parameters of the system and the ability to acceleration / deceleration of the engine to stabilize. Many sophisticated methods for open loop control enabled the system to approach the right pull-out, and anyway the dependence of motor torque at some reasons for steps must be taken into account, it must be sufficiently expert to contemplate the characteristics of torque / speed with the driver as building blocks for analysis. Variations of load and friction torque with speed also must be taken into account. The typical pull-out torque are shown in Figure 5.7 (a).

![Figure 5.7 Obtaining the optimum speed profile. a. - Features pull-out torque T (f) and load torque Tl (f). b. - Function 1 / [T (f)-Tl (f)].](/images/alciro/433_optencion-perfil-velocidad.png)

Figure 5.7 Obtaining the optimum speed profile.

a. - Features pull-out torque T (f) and load torque Tl (f).

b. - Function 1 / [T (f)-Tl (f)].

A reason for steps f the pull-out torque is indicated by T (f) and load torque TL (f) (corresponding to the pair of friction). If the engine is accelerated as quickly as possible, the maximum torque pull-out should be developed at all speeds. This pair wins the load torque (TL (f) friction torque) and accelerate the inertia of the system, expressed algebraically: